Blog

Why Smart Insulation & Ventilation Pay Off in an Environmentally Controlled Poultry Shed

Written by Stanley Kaye, MBA

Stanley has worked hands-on in the poultry industry for over 35 years, combining extensive field experience with a degree in economics and an MBA to deliver practical, profit-focused insights.

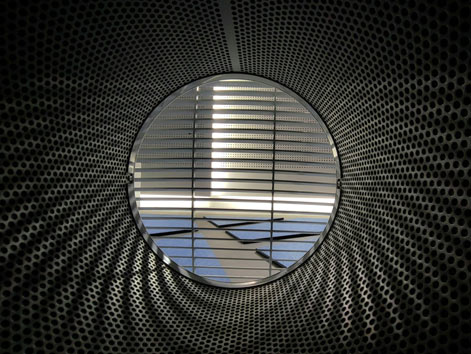

Poultry Shed

When you build a poultry shed, the bottom line is what matters. Insulating and ventilating properly isn’t about flashy materials — it’s about creating a stable micro-climate where every chook can grow or lay eggs at its genetic and economic potential.

A peer-reviewed, open-access study published in Animals (“Development and Validation of an Energy Consumption Model for Animal Houses Achieving Precision Livestock Farming” by Du et al., 2022) confirms that modest investments in improved insulation and ventilation design can lead to significant long-term savings in poultry farming.

1. Bird comfort = feed efficiency

Feed is by far the largest cost in chicken production. Poultry that are too hot or too cold burn feed calories to regulate body temperature instead of turning them into weight gain or egg mass.

The tighter the shed and the better insulated the easier it will be to achieve a constant microclimate in the shed and that will help with bird uniformity.

2. House-level thermoregulation beats bird-level

The model demonstrates that a well-insulated shell (e.g., 40–100 mm polyurethane wall panels combined with hollow-fibre ceiling blankets) can reduce heating and cooling energy demand by up to 22%—a much more efficient approach than relying on the flock to “pay” for comfort through their feed.

3. Design details that drive payback

| Design Element | What the Study Quantified | Real-World Benefit |

|---|---|---|

| Ceiling insulation | Halved winter heat loss | Lower heater runtime; birds stay comfortable 90% of the year |

| PU wall panels | 14–22% drop in total energy use | Reduced fan use—saves electricity |

| Balanced ventilation | Uniform air speed and relative humidity | Less stress, tighter weight spread, drier litter |

4. Sustainability bonus

A tight building with good thermal barrier results in fewer burner hours and reduced fan loads, cutting fuel consumption and electricity-related CO₂ emissions. A well-insulated, environmentally controlled poultry shed carries a lighter carbon footprint—supporting global climate goals and enabling the marketing of a truly sustainable poultry brand.

Agrotop Takeaway

Every Agrotop environmentally controlled chicken house is built with premium PU sandwich panels and hollow-fibre ceilings. Our in-house engineering team validates each design so growers invest just a few extra cents per bird in capital cost—and bank the savings in energy, feed efficiency, and carbon emissions over the life of the shed.

In the end, it’s still the bottom line that counts.

Citation

Du, L., Yang, L., Liu, T., Zhang, T., & Wang, Y. (2022). Development and Validation of an Energy Consumption Model for Animal Houses Achieving Precision Livestock Farming. Animals, 12(2580). https://doi.org/10.3390/ani12192580